The lab will advance additive manufacturing techniques such as cold spray, a technique where particles are blasted onto a material surface at low temperatures. The techniques are highly relevant to 3D printing, the rapid repair of machinery and the coating of materials to make them stronger. The research stands to benefit the manufacturing of next-generation vehicles and munitions while also boosting workforce development and activity across the economy.

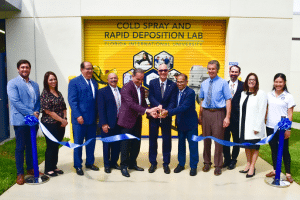

“FIU’s commitment to innovation and impact is on full display today as we celebrate the opening of this lab,” said Kenneth A. Jessell, president of FIU. “We show the world today that we are a leader for Army Research Lab Cold Spray Technology and an influential partner, together with our congressional delegation, in building up Miami’s tech, innovation and manufacturing ecosystem.”

The lab will be led by Distinguished University Professor Arvind Agarwal, chair of FIU’s department of mechanical and materials engineering at the College of Engineering and Computing (CEC) and a renowned expert on advanced additive manufacturing techniques.

“From developing antibacterial coatings for biomedical use to assisting in environmental corrosion prevention in coastal communities, these technologies promise to deliver solutions to a myriad of real-world problems, while helping to train the next generation of researchers, technologists and STEM professionals in the fields of robotics, advanced manufacturing, aerospace technologies and machine learning,” Agarwal said.

The opening of the lab positions FIU as a key provider of research and talent for the Department of Defense and industry partners, particularly due to the increase demand for electronics and the expansion of both the aerospace and defense industries.

“We have a large group of more than 25 researchers working on cold spray and rapid deposition technologies here at the College of Engineering and Computing,” said Ines Triay, interim dean of CEC. “This state-of-the-art lab, the only one of its kind at a Florida university, will allow us to not only augment our research capabilities, but also equip the next generation workforce with critically important skills.”

FIU’s research leadership and critical funding from the Army Research Lab has benefited from the strong support of the Florida Congressional delegation.

“I am so proud I was able to help secure the funding supporting the innovative solutions that FIU is developing, in this case helping to ensure our defense systems are agile and meeting the needs of our troops, while also bolstering the manufacturing ecosystem in South Florida,” said Congresswoman Debbie Wasserman-Schultz, Ranking Member of the Military Construction and Veterans Affairs subcommittee of the House Appropriations Committee.

Photos of the laboratory are available here.

Full story also available at FIU News.