The Department of Mechanical and Materials Engineering (MME) is part of the College of Engineering and Computing at FIU and offers a curriculum which is designed to give our students a thorough understanding of the basic laws of science and to stimulate and develop creative thinking, a professional attitude, economic judgment and environmental consciousness. The aim is to develop the students’ potential to the fullest, to prepare the students for superior performance as engineers, and to provide the students with the fundamental principles necessary for pursuing advanced study in the diverse fields of engineering, science and business.

FIU is developing a structural-monitoring system and prefabricated components – made off site and shipped for installation – to make possible construction of smaller, less costly nuclear reactors

Modular nuclear reactors, with minimal greenhouse gas emissions, tiny footprints and the ability to be built in even the most remote areas, are becoming a more attractive power source for the United States. With researchers and students from FIU’s College of Engineering & Computing working to tackle some of the major challenges facing nuclear power’s future, they are moving the nation one step closer to making these energy sources a viable option.

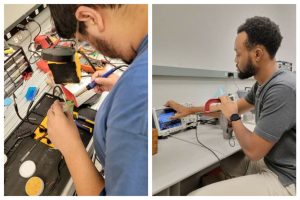

The endeavor is advancing with help from a Department of Energy $5 million, 5-year grant recently awarded to Professor Ibrahim Tansel and his team. The project, “Consortium for Research and Education in Cyber Manufacturing Applications for Modular Nuclear Reactors (CMA-MNuR),” also includes teams from the University of Central Florida, the University of New Mexico and Alabama A&M University, with guidance from the Idaho National Laboratory and Los Alamos National Laboratory.

As principal investigator (PI), Tansel works closely with co-PIs Professor Yiding Cao and Associate Professor Leo Lagos and a host of students to develop state-of-the-art cyber manufacturing capabilities, 3D printing of parts (also known as additive manufacturing) and installation of structural health monitoring (SHM) for modular nuclear reactors.

Read more at FIU News.