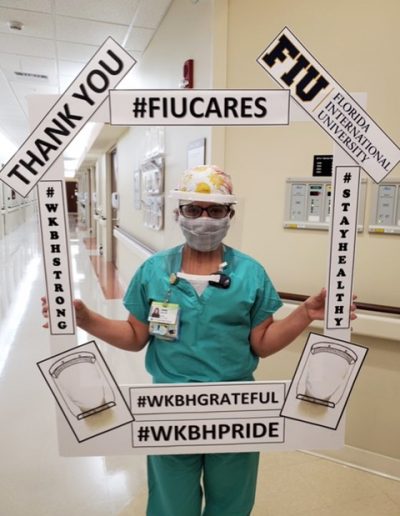

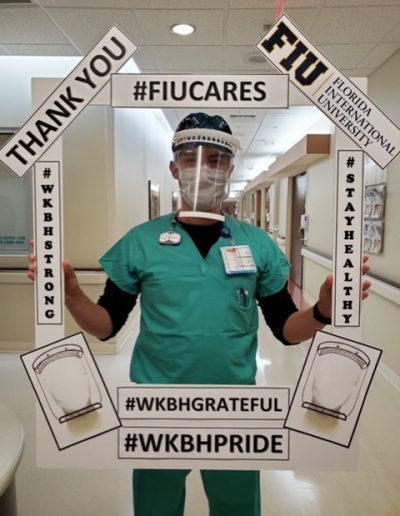

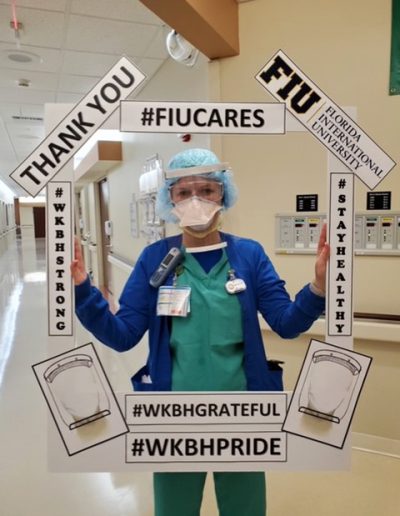

Face shields are part of the personal protective equipment that healthcare workers at Baptist Health wear when caring for patients who have or are suspected to have COVID-19. Baptist Health has 11 hospitals and more than 150 urgent care centers and physician offices in the four-county area from Monroe to Palm Beach counties.

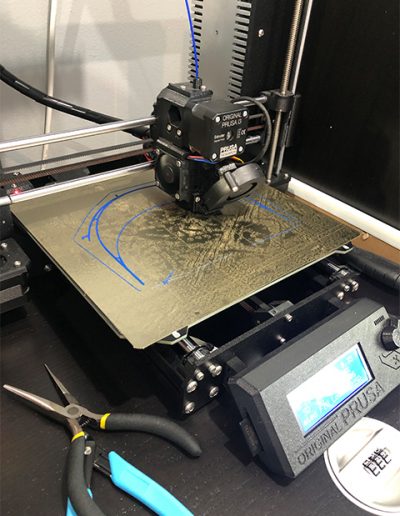

FIU’s College of Communication, Architecture, + The Arts (CARTA) is at the center of the initiative, mobilizing its 3D printing facilities, faculty, staff and students to produce a minimum of 1,000 face shields for Baptist Health. More than 30 3D printers housed in the college’s CARTA Innovation Lab in the Miami Beach Urban Studios (MBUS) are printing the protective equipment, as well as additional printers in the CARTA Robotics and Digital Fabrication Laboratory and the College of Engineering & Computing.

“As a university we wanted to find a way to leverage the skills, talent and resources of our students, faculty and staff to help these hard-working heroes who are risking their lives to save ours,” said FIU President Mark B. Rosenberg. “I’m proud of our collaboration with Baptist Health and hope it will pave the way for more opportunities to make a difference during these difficult times.”

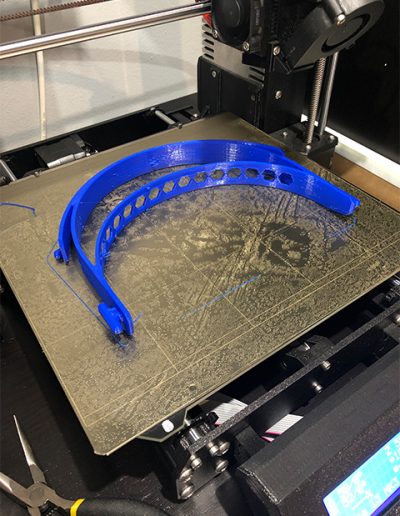

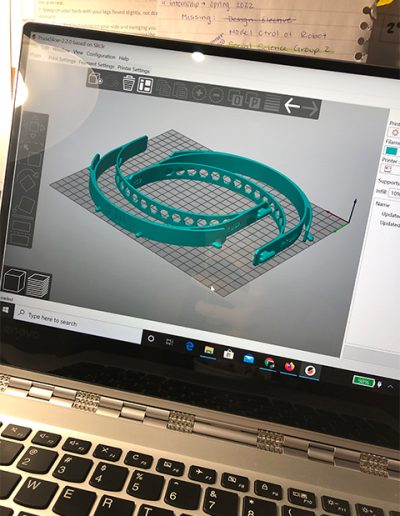

Architecture students working from home modified an open-source design for the face shields, which were then emailed to CARTA staff to print at home. The first printing of the prototype shields began on Saturday, March 21, just one day after the idea was presented to the staff and students. Students worked with Baptist Health leaders to ensure the specifications of the face shields were appropriate for patient care.

The face shields, made from non-toxic PLA (polylactic acid), are meant to act as a first line of defense for healthcare workers. With the shortage of masks, the shield is worn over the mask to preserve their longevity as well as prevent infected respiratory droplets from entering workers’ nose and eyes.

The shields are being sent to Baptist Health South Florida for use in their hospitals.

“Out of adversity creates opportunity,” said Dr. Barry T. Katzen, founder and medical director of Miami Cardiac & Vascular Institute, who has long been a leader in innovation at Baptist Health. “This partnership with FIU is community collaboration at its best, bringing together an academic institution and a healthcare system by using innovation during a time of urgent need.”

The FIU team that includes Brian Schriner, dean of CARTA; and Bridget Pelaez, assistant director of FIU’s Department of Emergency Management; collaborated with Baptist Health on the idea and design. Others involved include John Stuart, CARTA associate dean of cultural and community engagement and executive director, MBUS; Colette Mello, senior special events manager, MBUS; Jacqueline Thompson, program manager, MBUS; and students Brett Serfozo, Raymond Reina and Diana Vazquez, all of whom are pursuing master’s degrees in architecture.

“I am extremely proud of our colleagues’ creative problem-solving expertise and their unyielding commitment to the safety and well-being of our community each and every day,” Schriner said.

Read the article at FIU News.

The College of Engineering & Computing (CEC) is immensely proud of its faculty members and dedicated students who are behind the scenes, printing the non-disposable face shields from their own homes for the front line defenses against COVID-19 to use.

To date, CEC has contributed 2,380 face shields to Baptist Health South Florida. With more faculty and students joining forces, the number of non-disposable face shields produced by CEC has increased. The first delivery on March 28th consisted of 59 non-disposable face shields. In the latest delivery, that took place on April 10th, 409 face shields were delivered!

“All of the Front Line people are so appreciative of our efforts, as well as those that are doing all the coordinating, assembly and packaging of these units. It is definitely a team effort. I want to thank EVERYONE involved for their continued efforts.”

-Richard Zicarelli, coordinator of the Engineering Manufacturing Center

Let’s take a moment to thank the following individuals for making the health of our community a top priority by working non-stop in printing and delivering the non-disposable face shields to Baptist Health medical professionals:

Engineering Students:

- Aleksander Aleman

- Ian Briggs

- Elisa Cristano

- Issac Ghobrial

- Kevin Leiva

- Camila Madera

- Ricardo Maury

- Edwin Robledo

- Kumar Shah

- Tomas Suarez

- Tony Thomas

Department of Mechanical and Materials Engineering

- Ibrahim Tansel, professor

- Andres Tremante, senior instructor

- Richard Zicarelli, coordinator of the Engineering Manufacturing Center

Department of Electrical and Computer Engineering

- Ou Bai, associate professor

- Grover Larkins, professor

- Yuri Vlasov, lecturer

Department of Biomedical Engineering

- Yun Qian, instructional laboratory coordinator

- Jessica Ramella-Roman, associate professor

FIU CARTA MBUS: Jacqui Thompson, Colette Mello, Sergio Aquino, John Stuart, Brett Serfozo, Diana Vazquez and Raymond Reina

FIU CARTA LABS: Mike Bisnett (FIU School of Architecture Print Lab); Hadi Alhaffar and Sam Moore (FIU RDF Lab) have been 3D printing.

FIU HONORS COLLEGE EDGE LAB

FIU FAST: Bridget Pelaez, Hugo Duenas and Victoria Villa have been cleaning, assembling and safety/quality control protocols.

Outside engineering volunteers 3D printing: Peggy Zicarelli, Amy Collash, Clara Villalba and Elisa Cristino.

Visit FIU’s Miami Beach Urban Studios website for more information on the FIU-BHSF 3D Printed Face Shield Open Source.